Magazine

Nachhaltig, sozial und flexibel: Coworking im neuen NOI Techpark Bruneck

Wir sind NOI.

Südtirols wachsendes Innovationsviertel.

Wir sind NOI.

Südtirols wachsendes Innovationsviertel.

Der Ausweg: CO₂-neutral werden. NOI ist Teil des Südtiroler Ökosystems, das sich mit grünen Technologien beschäftigt. Gemeinsam erforschen wir Lösungen. Entwickeln marktfähige Produkte. Testen Geschäftsmodelle. Unternehmen, Start-ups, Forschungsinstitute und Tech-Transfer-Fachleute arbeiten an drei Schlüsselthemen: Energiesysteme, nachhaltige Gebäude und Stadtviertel, Wassertechnologien.

Mehr als Essen und Trinken. Im Innovation Ökosystem Food & Health leisten wir Pionierarbeit. Wir entschlüsseln natürliche Prozesse und Inhaltsstoffe. Verwerten Nebenprodukte. Nutzen das Wissen der Biomedizin für präzise Gesundheitsservices. Mit Forschenden, Unternehmen und Start-ups arbeiten wir an drei Säulen: Rohstoffe&By-Products, Optimal Processing&Fermentation, Omics&Precision Health.

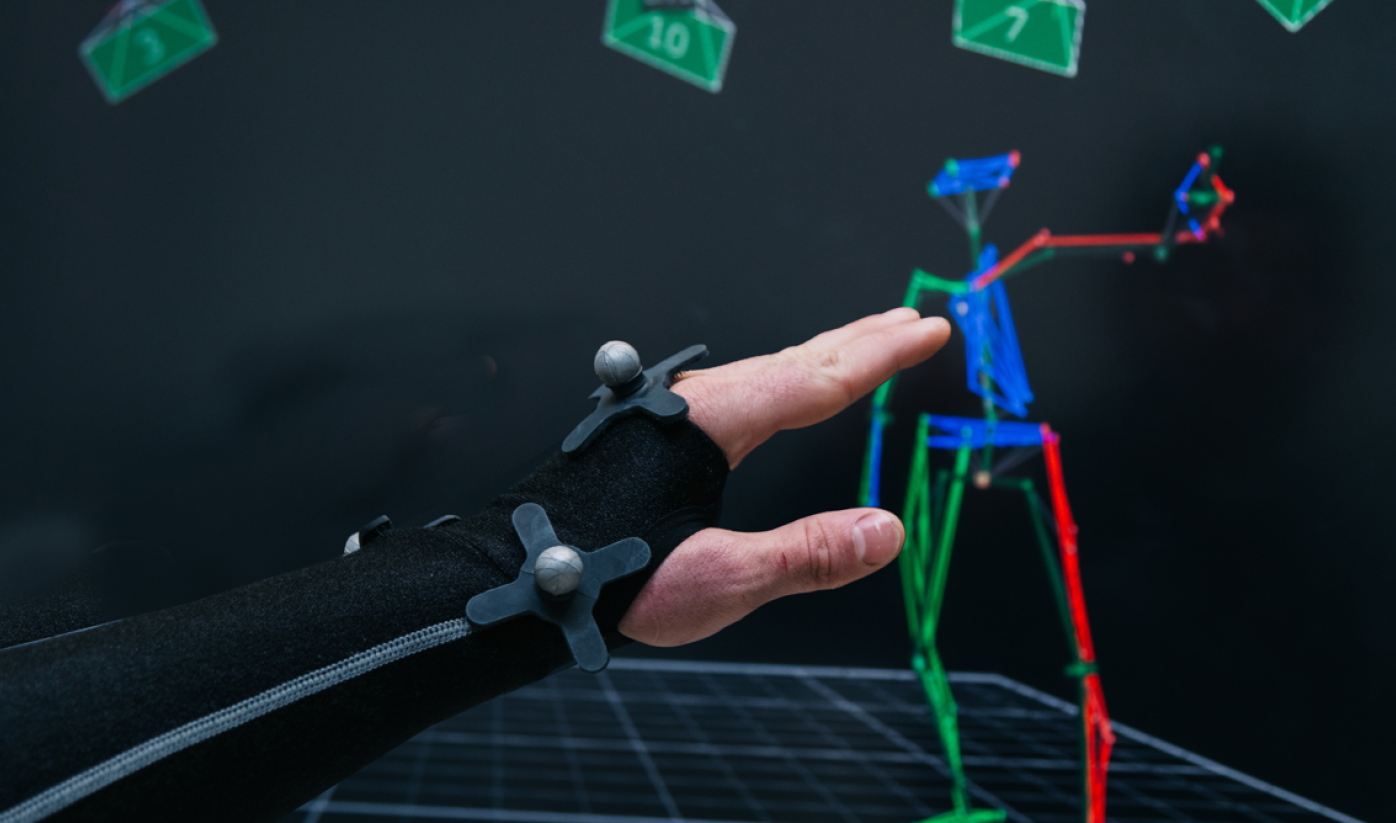

Flüssiger Verkehr, sichere Lebensmittel, lernende Häuser und Maschinen: Daten liefern die Basis für kluge Entscheidungen. In Zukunft sollen sie autonom und in Echtzeit unser Leben einfacher machen. Im NOI schaffen wir die digitale Basis für smarte Regionen. Forschende, Studierende und Tech-Transfer-Fachleute sind in drei Bereichen führend: IoT, Open Data Hub, Künstliche Intelligenz.

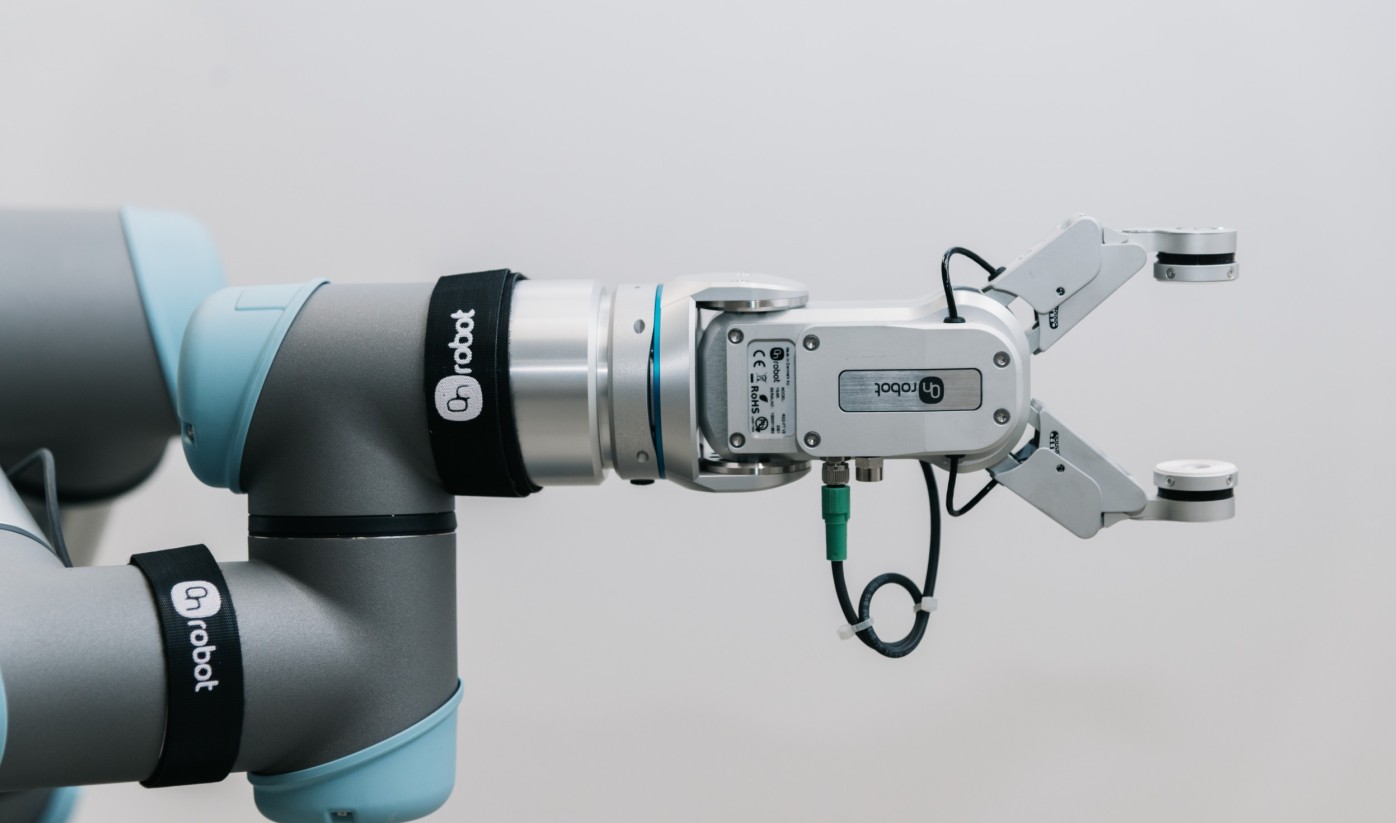

Industriebetriebe stemmen das Gros der F&E-Investitionen in Südtirol. Vornedran: Automobilzulieferer. Alle vereint ein Zukunftsszenario: Menschen ergänzen Maschinen, Maschinen stärken Menschen. Sprich: nachhaltige Fertigungs-, Automobil- und Mobilitätslösungen. Forschende, Studierende und Tech-Transfer-Fachleute arbeiten an drei Säulen: Automotive&Mobilität, Manufacturing, Agri-Automation.

Browse unseren digitalen Branchenüberblick.