Everything you need to know as a company

By hook or by crook

Tensile tests, compression tests, punching tests and more: we research the properties of materials

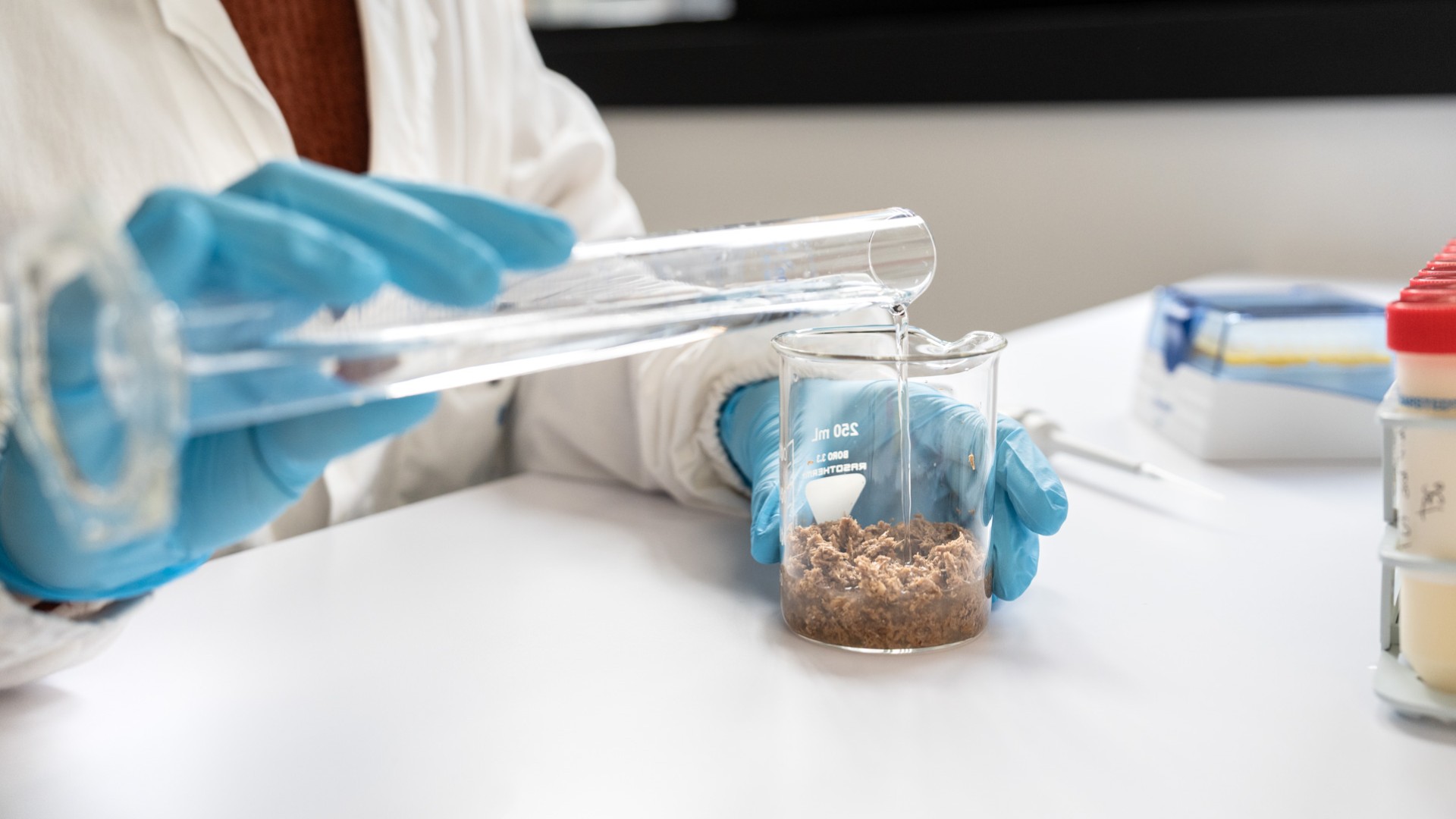

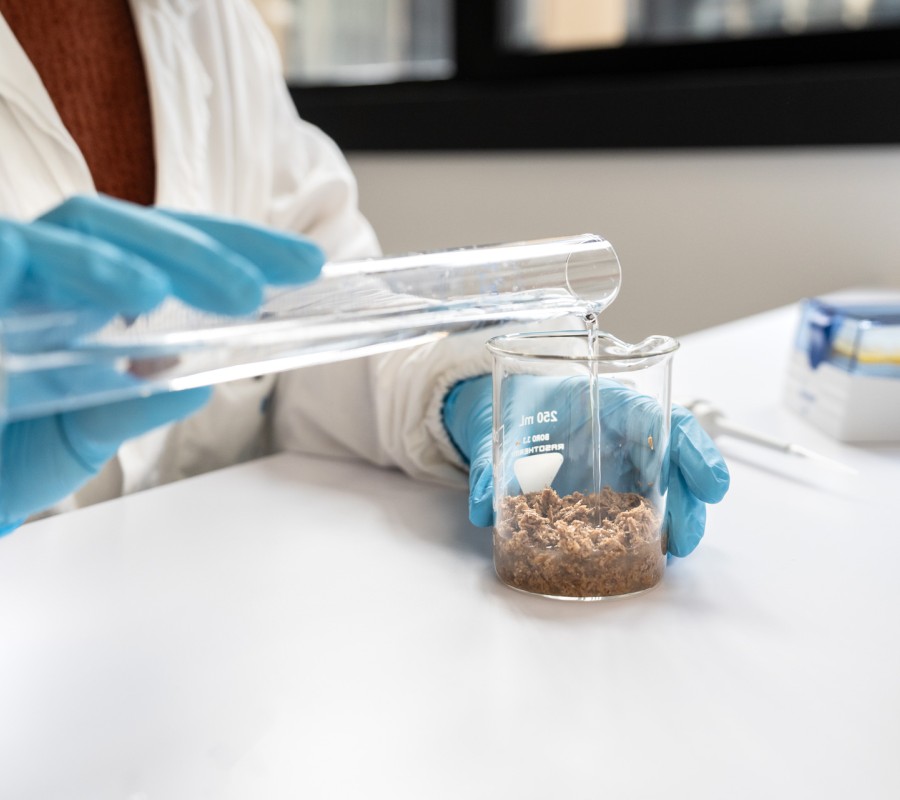

How do metals, concrete, polymers, wood and fibre-reinforced composites and materials for 3D printing or additive manufacturing behave under tension, compression or punching? How flexible are they? What is the performance and durability of gears and bearings? These are the questions we explore in the Materials Characterisation Lab, working in close collaboration with industry and research partners.

We test, analyse and determine the mechanical properties of various materials and components, investigating their fatigue behaviour under both high-cycle and low-cycle conditions. We use metallographic equipment to examine fracture surfaces and develop and calibrate material laws and damage models. Our expertise extends to analysing bending fatigue, efficiency and wear fatigue in gears, as well as the lubrication effect in bearings using a specialised test bench and advanced CFD analysis. Additionally, we use mechanical analyses to help design and optimise sports equipment, such as skis and roller skis.

The Materials Characterisation Lab carries out accredited testing.

Key tools

MTS Criterion 45 tensile testing machine (100 kN load capacity, 1220 mm stroke)

STEP-LAB UD04 (5 kN load capacity, 500 mm stroke)

Gears test bench (speed range 1-4000 rpm, torque up to 10 Nm, adjustable centre distance 20-150 mm)

Bearing test bench

Hardness and micro-hardness testers, equipment for metallographic sample analysis

Optical and electron microscopes

Digital image correlation (DIC) analysis camera

Our services

Quasi-static tensile and compression tests, bending and punching tests, high-temperature testing

Dynamic tensile and compression tests with high and low cycle times

Tests on gears with a small module

Tests of meshing gears with parallel and orthogonal axis configurations, thermal tests from -5 °C to 150 °C and thermal imaging

Lubricant flow testing and lubrication analysis using particle image velocimetry (PIV)