Everything you need to know as a company

Food intake and food transformation

Six labs, three pilot plants: a large-scale set-up for food fermentation.

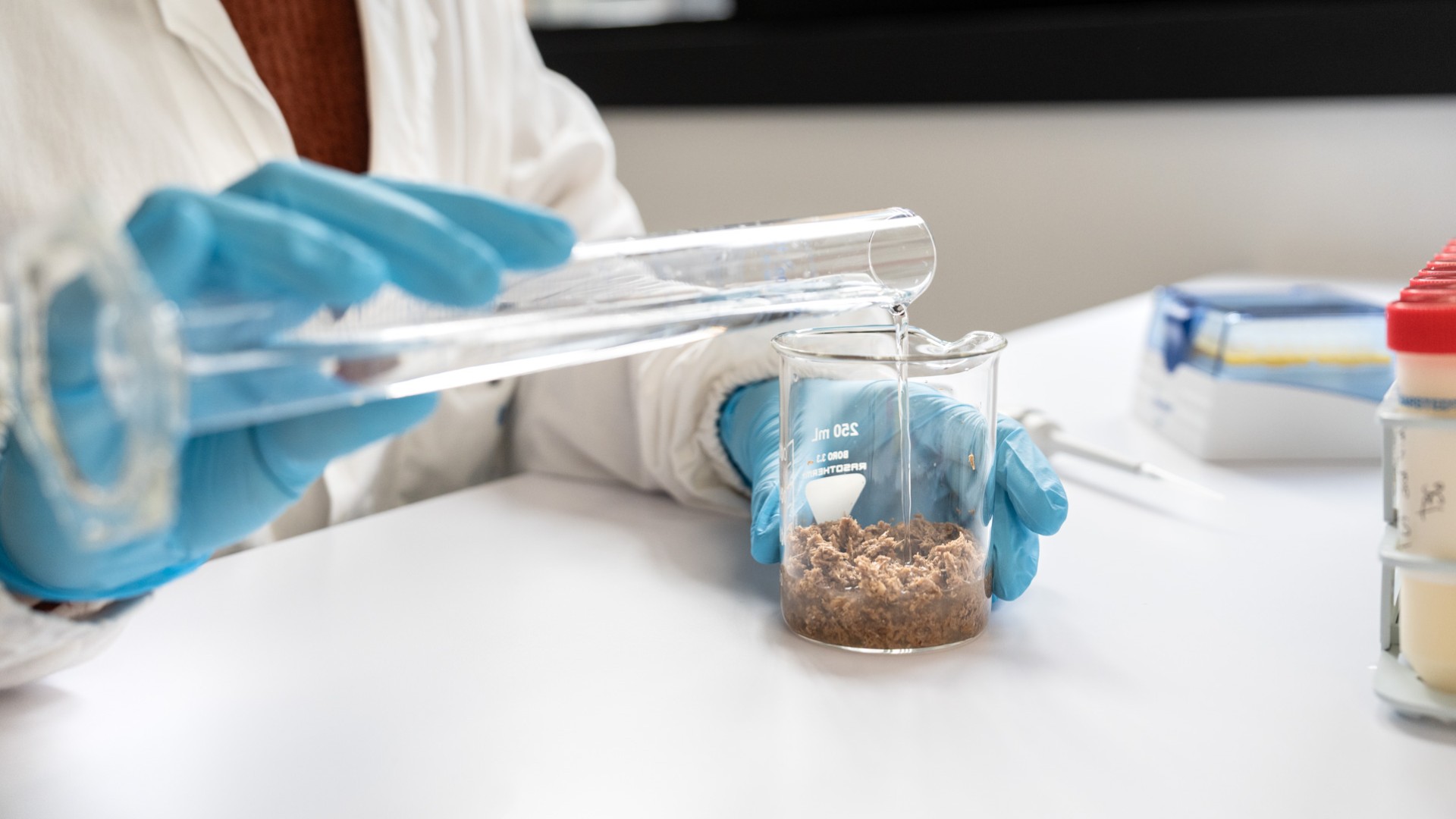

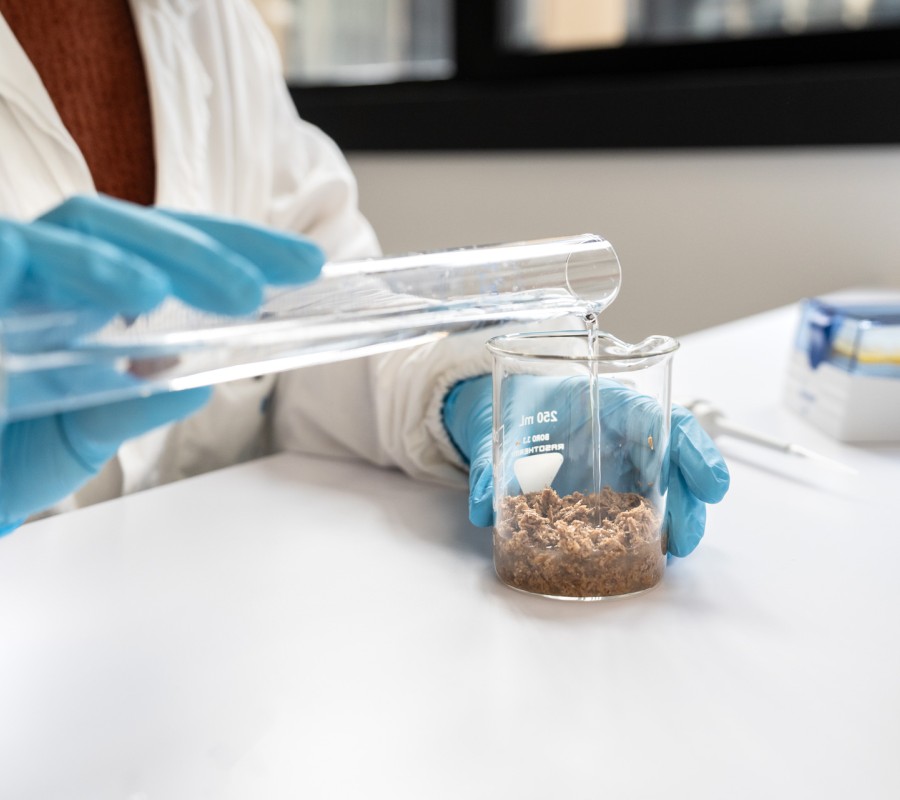

Micro4Food Lab is a research platform of six complementary laboratories and three pilot plants that studies the transformation of food. Our goal is to use the advantages offered by fermentation to improve the nutritional, functional and organoleptic properties and shelf life of food. To do this, we develop new processes and products and utilise waste and by-products from the food chain.

Specifically, our scientific team is working on two main research areas:

1. Fermentation in food, aiming to develop new products with special functional properties.

2. The human-food axis, in particular, food intake/food conversion and the intestinal microbiome.

Protocols for fermented foods and the production of microbial biomass.

The Micro4Food platform is equipped with high-tech devices that allow the creation of biotechnological protocols for the development of fermented foods and the production of microbial biomass. We primarily focus on yeast bakery products, milk derivatives (dairy drinks and cheese) and fruit and vegetable-based fermented foods.

The advanced 'Omics' laboratories (phenomics, proteomics, metabolomics) occupy an area of approximately 450m² and are equipped with instruments for chromatography and mass spectrometry, microbiology and biotechnology, as well as food technology. We also have pilot and semi-industrial facilities for the production of fermented foods and microbial biomass in an area measuring approximately 150m².

Below is the equipment list of each laboratory, which complement each other in their work:

1. Microbiology laboratories: safety cabinet, autoclaves, freezers, refrigerators, cookers, centrifuges, CO2 and non-CO2 incubators, stirrers, thermostatic baths, spectrophotometers, microscopes and magnetic stirrers.

2. Molecular biology laboratories: safety cabinet, PCR, real-time PCR, MultiNA microchip electrophoresis system, UviTEC gel documentation system, nucleic acid and protein purification and isolation system, electrophoresis apparatus (nucleic acids), NanoDrop, refrigerated centrifuges.

3. 'Omics' labs: Ultra-high pressure liquid chromatography (UHPLC) coupled with mass spectrometer, ÄKTA™ pure chromatography system for the purification of proteins, peptides and nucleic acids, OmniLog® Phenotype Microarray (Biolog), Proteomic gel-free platform, Orbitrap model Q-Exactive high-resolution spectrometer coupled with U3000 Nano RSLCnano system for Easy-Spary, gel-based proteomics platform (one- and two-dimensional electrophoresis systems) combined with Image Lab densitometer software.

4. Microscopy lab: optical, fluorescence and confocal microscopy.

5. Nutrition-human axis laboratory: simulator of the human gut microbial ecosystem (SHIME®).

6. Semi-industrial pilot plants: one for the production of bakery products: 'Bakery Inspirience' and measuring instruments for the rheological characterisation of yeast baked goods, OXITEST and extraction and digestion system of soluble and non-soluble fibres; one for the production of dairy products; one for the production of microbial biomass and fermentation of plant matrices.

Visit website